Laboratory testing delays and inconsistencies aren’t usually a good thing. But sometimes, those very frustrations can cause innovation to spark.

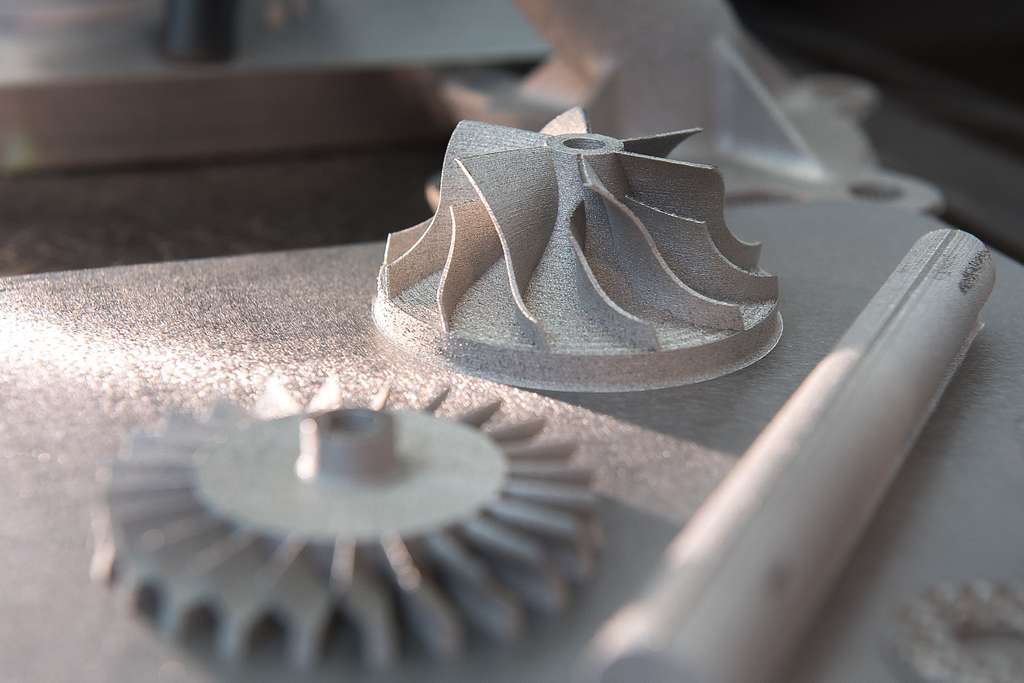

College of Engineering Early Entrepreneur in Residence postdoc Dr. Luis Izet Escaño Vólquez and Mechanical Engineering professor Dr. Lianyi Chen, co-founders of 3D Powder Tech startup, have spent years studying the delicate process of turning powdered metal into customized parts using layers and layers of laser-melted material. To create defect-free parts for aerospace, biomedical, and automotive industries, this printing process requires metal powder to spread easily and evenly.

Escaño is from the Dominican Republic, where he earned his bachelor’s degree in mechatronics engineering (a multidisciplinary field integrating mechanical engineering, electrical engineering, computer science, and software engineering to develop automated systems) at the Instituto Tecnológico de Santo Domingo. After graduating, he spent a year working as a production line supervisor.

As he realized his interest in developing technologies, he moved to the U.S. to pursue a Master’s degree—and later enter the PhD program—in manufacturing engineering at the Missouri University of Science and Technology as a student of Chen. He researched powder dynamics and processes in laser powder bed fusion, developing the first device compatible with X-ray imaging to study powder spreading in additive manufacturing. This device is the base for what would become 3D Powder Tech.

With two years left in his PhD program, Escaño transferred to UW–Madison with Chen. They continued to test new and existing metal alloys for implementation in additive manufacturing. The team quickly found that the process was challenging and unpredictable, as there were no existing powder qualifications standards to ensure the proper melt needed for defect-free parts. This not only resulted in waste, but in delayed lab research.

So, the team set to work reenvisioning powder dynamics to better predict the spreading process in 3D printing conditions. Their innovative method utilizes in-situ X-ray imaging to analyze the spreading process at a particulate scale, utilizing the first-ever X-ray compatible powder spreading additive manufacturing machine that they designed. They then extended into more ambitious additive technologies under more complex conditions, such as those found in space. This resulted in a unique, first of its kind, X-ray compatible Electron Beam Melting system that completed their innovation path.

“The study provided new understandings of powder behavior, which led us to create and patent a novel method to test the powder’s usability and performance for metal 3D printing,” said Escaño.

Once their device prototype was up and running, the team realized its many applications in commercial or real-world processes: incorporating novel materials in the production lines, accelerating production through quicker material testing and qualification, increasing printing success rate across 3D metal manufacturing, and enhancing powder recycling.

Escaño and Chen then decided to bring their testing technology to the metal additive manufacturing market. By the end of Escaño’s PhD program in 2023, he and Chen received a WARF patent titled “Powder Deposition Apparatuses and Methods,” which legally protects their innovative powder testing method. During Escaño’s subsequent postdoc at UW, his team took the first steps toward commercialization and pursued campus resources to learn about entrepreneurship, such as Igniter from D2P and NSF I-Corps from TEO. The team also attended the Additive Manufacturing Users Group (AMUG) conference.

I-Corps™ was critical in the entrepreneurial process. The program provided the team early entrepreneurship education, including processes, terms, and practices to take innovation to the marketplace. It also offered additional training on how to interview customers, gather data, and analyze feedback when exploring marketing venues. In summer 2025, Xiujuan Jane Zhang, director of the Advanced Materials Industrial Consortium, mentored Escaño and his team throughout the National Program. This 7-week intensive course awards increased funding and more detailed evaluation.

“I-Corps greatly helped us to organize and establish a better approach in our business. It is a highly recommended experience for those seeking to be entrepreneurs and to acquire the proper skillset and mentality to be successful,” said Escaño.

The biggest challenge Escaño notes from his startup journey has been shifting from a research-oriented mindset to a commercial one. “The skillset and mentality required to bring technology into market are very different from those required at a laboratory. The ability to create a network and pull individuals to believe in your vision is an art in itself,” he said.

He has also learned many valuable lessons from the entrepreneurial experience that he would not have learned in the lab alone. The most essential of these? Being open-minded and a good listener. “Your solution, despite being of your own creation, is not perfect and is full of flaws that only customers can bring up,” he continued. “You must constantly be able to change and adapt to the market and the customer’s desires. New technology cannot translate into a business if it’s not tailored for the users.”

Escaño and Chen anticipate a bright entrepreneurial future. As their business grows, they are continuously analyzing their business model and asking how other technologies might be implemented. They expect to be leaders of powder qualification in the 3D printing industry—in fact, a new generation of printers might leverage 3D Powder Tech’s understanding of the manufacturing process. Sometimes, short-term lab delays can result in long-term progress.

• • •

Feature image: Drs. Luis Izet Escaño Vólquez (right) and Lianyi Chen (left) discussing 3D Powder Tech in their lab at UW–Madison. Photo from Escaño Vólquez.

Written by: Bri Meyer